Business area

- FMS

- Man Power Service

- Flushing

- Chemical

- Oil

- Water

- Water Jet

- Pressure Test

- Cleaning

- Pig

- Passivasion

- Piping Installaion

- Offshore Plant

Chemical Cleaning Procedure

1. Inspection and acceptance criteria

1. Perform visual inspection and confirm the surface is clean and free rust, slag, scale, paint, oil, grease and hydrocarbons, etc.

2. Cleanliness shall be inspected by dropping out spools if required by COMPANY.

2. Chemical cleaning Equipment & piping systems

1. Following equipment’s will be required for chemical cleaning and passivation works.

- Acid mixture tank

- Storage Tank

- Pipes, Flanges, Hoses, Ball Valves, Pickle Filters

- Boiler for heating/steam unit

- Heater for drying

- PH meter, Dew Point Meter, Safety Outfits, Inspection Equipment, Etc.

2. As a minimum the following piping system shall be chemically cleaned:

- Lubrication oil

- Seal oil/gas or other seal fluids

- Fuel oil/gas (critical parts only)

- Relevant part of gas compressor suction lines

- Process discharge to anti-surge control and safety relief valves

3. Purpose of chemical cleaning

Chemical cleaning (descaling) is carried out to remove scale from piping thereby protecting downstream equipment from its detrimental effect.

Cleaned, chemical cleaned (descaled) and passivated pipe shall be free of scale, rust, weld flux, oil, grease and other foreign materials.

4. Preparation of chemical cleaning

Chemical cleaning will be carried out after ‘proof’ pressure testing (or before oil flushing, if oil flushing is applicable).

Chemical cleaning solutions should not be allowed to contact any parts of process equipment or in-line instrument. Following parts that may be damaged if in contact with acid shall be disconnected or isolated prior to chemical cleaning.

1. Control valves (PV, TV, FV) including check valves and relief valves.

2. All kind of gauges

3. In-line instruments such as Flowmeters, Turbine meters, rotameters, Orifice plates, venturi tubes etc.

4. Instrument tubing

5. Pressure Relieving Devices (Rupture discs, Relief valves)

6. Flame Arrestors

7. Filters and strainers

8. Piping components that contains elastomeric seals, chrome or nickel plating or galvanized coatings

Disconnected or isolated parts shall be cleaned separately.

The systems to be cleaned shall have high and low point vents and drains installed. “dead legs” shall be avoided.

Careful selection of chemical cleaning solutions and inhibitors shall be made prior to chemical cleaning to avoid any excessive corrosion of pipe metal by chemical cleaning solution. Test samples that are representative of all material in the piping system (corrosion coupons) shall be dipped in chemical cleaning solution to monitor corrosive effect, treatment time and cleaning efficiency of the solution on the piping system.

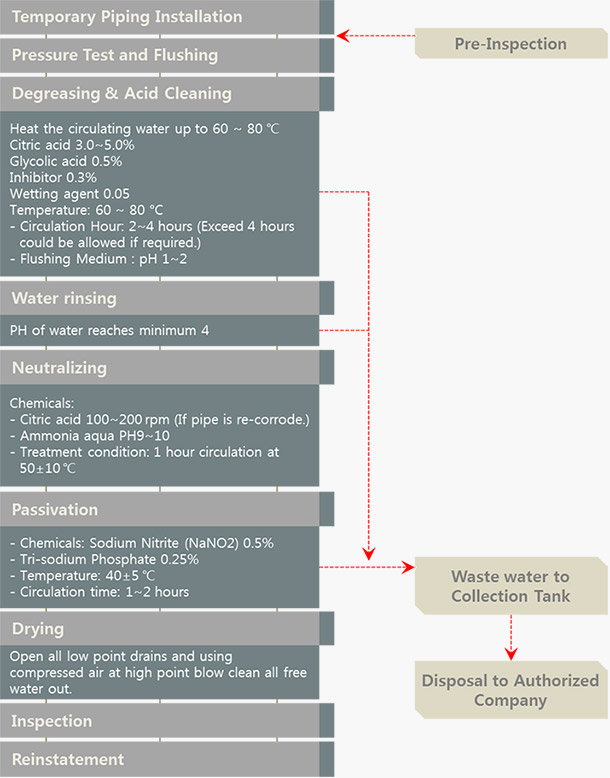

1) Start water circulation and make sure that every connection point is tightened.

2) Heat the circulating water up to 60 ~ 80 ℃ and inject chemicals into the system (Medium velocities : 8 m/s). The following chemicals are suitable for the degreasing and acid cleaning simultaneously.

- Chemicals : Citric acid 3.0~5.0%

Glycolic acid 0.5%

Inhibitor 0.3%

Wetting agent 0.05%

- Temperature : 60 ~ 80 °C

- Circulation hour: 2~4 hours (Exceed 4 hours could be allowed if required.)

- Flushing medium : pH 3~ 12

- Cleanliness level: Mediums used for flushing shall have a cleanliness level in accordance with ISO 4406, class -/14/10 prior to flushing start.

3) Drain solution into reservoir.

6. Water ringing

1) Flush the system with clean fresh water and drain solution into the reservoir and continue flushing until PH of water reaches minimum 4.

2) Refill the system with clean water

7. Neutralizing

1) Chemicals: Citric acid 100~200 rpm (If pipe is re-corrode.)

- Ammonia aqua PH9~10

2) Treatment condition: 1 hour circulation at 50±10 ℃

8. Passivation

1) Heat the circulating water up to 40± and progressively add chemicals into the system. The following chemicals are suitable for the passivation chemicals.

- Chemicals: Sodium Nitrite (NaNO2) 0.5%

- Temperature: 40±5 ℃

- Circulation time: 1~2 hours

9. Drying

1) Confirm the piping system is fully drained paying attention to find any dead legs.

2) Open all low point drains and using compressed air at high point blow clean all free water out.

3) 3) Check that the piping system is drained and free of water again.

10. Protection

1) After reinstatement of components isolated/removed during chemical cleaning operations, all opening in cleaned system will be sealed with cap, plugs or blind flanges.

2) System shall be packed with such a manner as below.

3) Flange and other plug in the closed system should be connected and bolted tightly.

4) Dry chemical not appropriate for long pipe runs as coverage is not possible.

[BEFORE]

[AFTER]

* Chemical Flushing Process Diagram

Korean

Korean English

English