Business area

- FMS

- Man Power Service

- Flushing

- Chemical

- Oil

- Water

- Water Jet

- Pressure Test

- Cleaning

- Pig

- Passivasion

- Piping Installaion

- Offshore Plant

Waterjet Flushing Procedure

WATERJET Flushing

Waterjet flushing shall be used to clean the piping for removal of foreign materials such as weld slag, blast grit, sand, trash, dirt, loose scale and other debris.

The flushing medium shall be fresh water with chloride ion content less than 200 ppm and the certificate of flushing medium to be provided.

The initial flushing shall be carried out prior to pressure testing. According to the circumstances, however, water flushing may be carried out after pressure testing for piping system. Any sequence change shall be approved by COMPANY inspector.

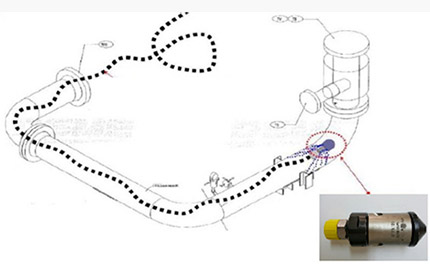

Flushing of piping by water jet flushing shall be applied where closed looped flushing is not applicable. And prohibit inside galvanizing or paiting.

A rotating nozzle may be used for 6" to 28". Large diameter piping 30" and above can be mechanically cleaned, or a water spray from a hose might be sufficient if there is only dust on the walls.

For piping with normal pipe size (NPS) below 4", High Velocity Water Flushing (HVWF) may be used. Water velocity shall be minimum 10m/sec (33ft/sec). On system where high pressure jet flushing can not be used due to complicated pipe configuration and/or long runs HVWF may be used. This type of flushing normally involves taking a section of piping and flushing it from a "start point" to an "end point". Additional pumping capacity (with pump, tank and filters) will be required to obtain the minimum flow. Flow meter to be provided to prove adequate flows.

After completion of Waterjet flushing, the piping systems shall be completely drained and protected against corrosion.

<Water jet nozzle will be inserted in piping within the test boundary>

Korean

Korean English

English